Short Warranty Rationale

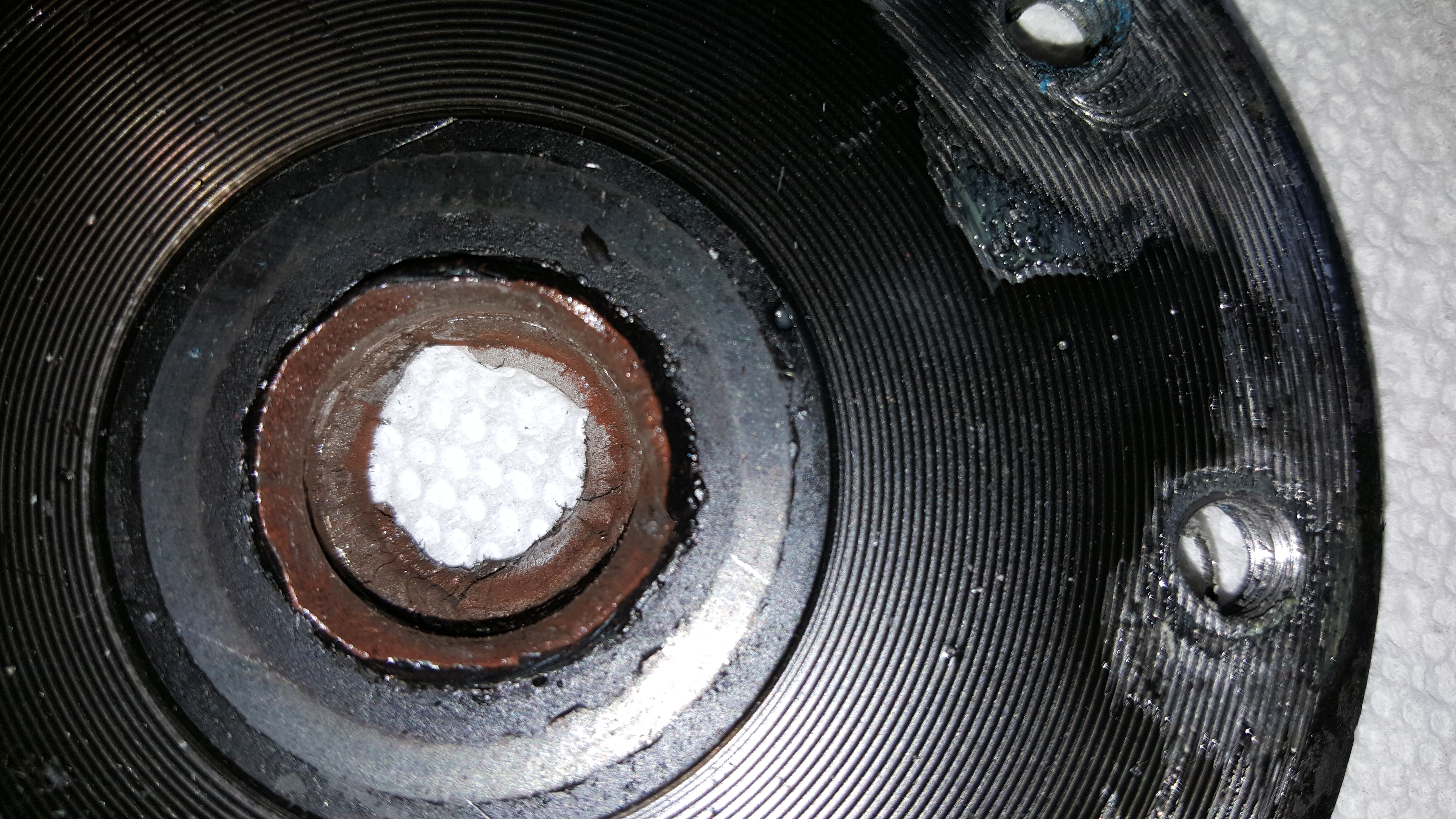

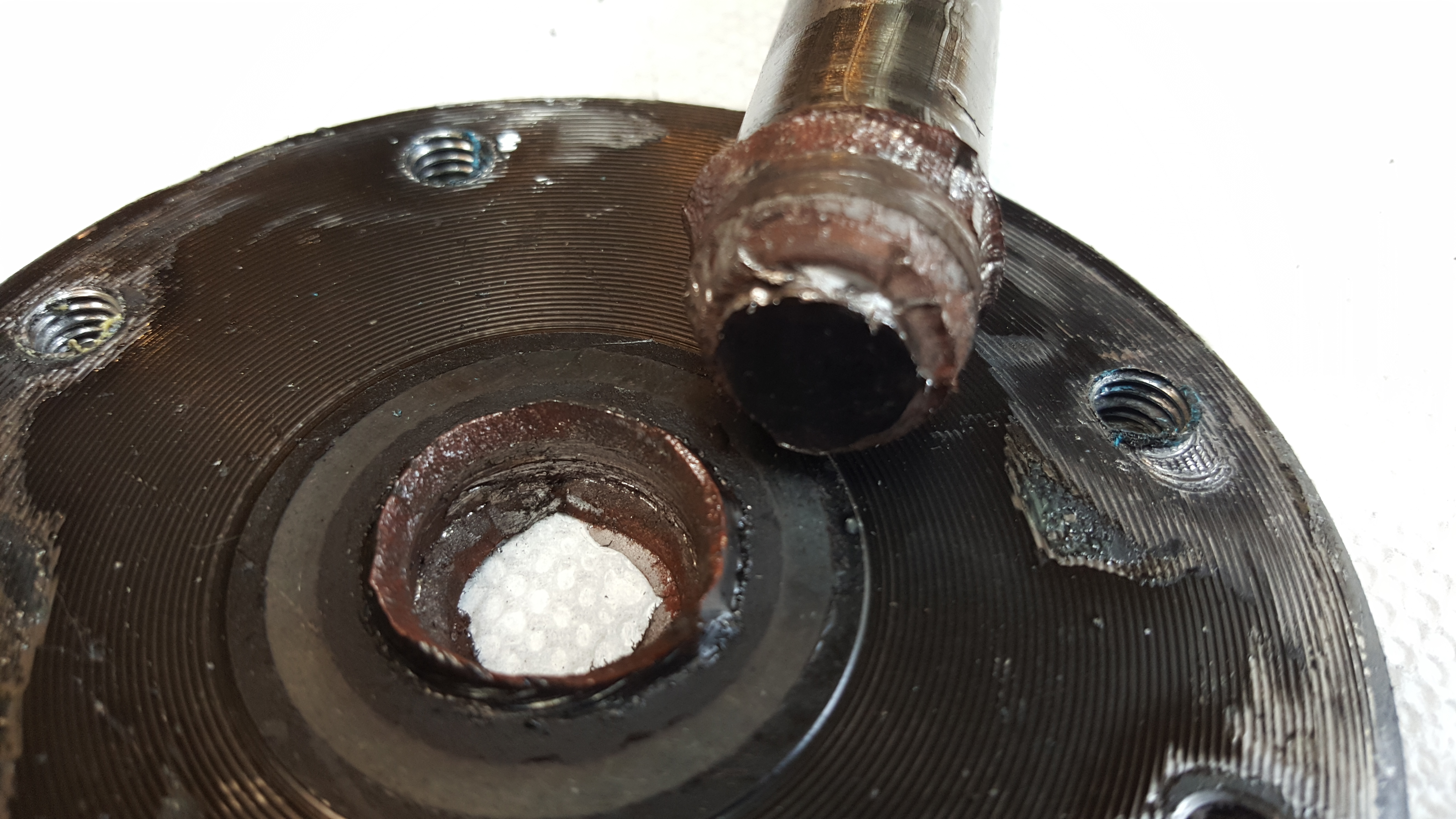

The broken crank from my +ProForm elliptical trainer. Terrible welding. Only a tiny bit of the welding was actually a through weld. Mostly cold welds rusted through. This is definitely a manufacturing defect. No wonder ProForm (ICON) offers only a 90 day warranty. Paying over $110 for a replacement for this piece of junk part is clearly not a winning idea.

Ed Bailey May 09, 2015 10:09

With all that rust it makes one wonder if their manufacturing process includes a step where the part gets a salt-water bath…

Scudder Mead May 09, 2015 10:12

+Ed Bailey nah that’s the part that happens on the freighter inbound from China.

Darren Hart May 09, 2015 11:48

Could you have it welded properly now that you have it out?

Michael K Johnson May 09, 2015 12:25

Well, I had to destroy some of the screws to get it out. I need to buy a new grinder, and then I do intend to try to weld it. But I don’t have a jig and if it is not orthogonal, the belt won’t work. And then I’ll need to find enough compatible hardware to put it back together. I’m not optimistic.

At least 90% chance I’m just buying a new elliptical trainer. :-(

Darren Hart May 09, 2015 12:52

Good luck

Edward Morbius May 09, 2015 17:11

I’d suggest rethinking your excercise equipment choices.

I’m a fan of kettlebells (you can substitute a dumbbell). Very few moving parts.

If you insist on equipment, Concept 2 Rowers.

$750 -$850 in the Washington, DC, area.

http://washingtondc.craigslist.org/search/sss?sort=rel&query=concept+2+%28row%7Crowing%7Crower%29

$395 in Raleigh.

http://raleigh.craigslist.org/search/sga?sort=rel&query=concept+2+%28row%7Crower%7Crowing%29

Michael K Johnson May 09, 2015 19:45

We have dumbbells. I use a treadmill for cardio. My wife and kids prefer the elliptical.

Michael K Johnson May 09, 2015 19:51

Blessed are the pessimists,

For they shall never be disappointed.

Blessed are they that presume the worst,

For they shall sometimes be pleasantly surprised.

I’ve never before tried to use a MIG welder to weld ~3/8” plate to ~3/4 rod. It’s not the right tool for the job, but I don’t have a stick welder. I’m running out of argon. I had to spend half an hour carefully filing out my minor mistakes, and it’s ugly. But it works, for now. I ran aggressively, changing direction as suddenly as possible, and no hint of impending failure. It’s probably stronger than it was when we purchased it.

Now we can take our time and do research before spending more money on a higher-quality unit. ☺

Michael K Johnson May 09, 2015 20:12

+Darren Hart I guess you get credit for the assist for wishing me good luck… I didn’t have time to buy a grinder so I just chucked the tools in a cordless drill. I can’t say it’s welded properly though. :-)

Edward Morbius May 09, 2015 20:33

+Michael K Johnson Kettlebells are principally energy systems work (cardio), though with a strength component.

Michael K Johnson July 09, 2015 21:35

Oh, well. Broke again this morning.

Do I buy a new elliptical, or invest in a lathe and maybe a stick welder? Hmm.

Michael K Johnson July 10, 2015 22:55

A bench grinder ($60) and a welder’s magnetic square ($11) were all I needed. A machinist’s try square ($13) verified that the magnetic square worked. Didn’t end up using the angle grinder ($40) at all. (I want it anyway for other work, so I don’t regret getting it.)

Ground off the whole old bead, cleaned everything well, and did what I think is a better job of welding. The beads mostly are decent fillets for a newbie. Went much quicker this time. Have to wait until tomorrow morning to put it back together, but that should be quicker even than taking it apart.

The only fly in the ointment is that I am more or less out of argon, so I used flux core wire and had lots of spatter that adhered to the part to clean up after welding.

Darren Hart July 10, 2015 23:35

Wow. Impressive. You didn’t include the time in your component list. I find that’s that’s the hardest part to source locally…

Michael K Johnson July 11, 2015 06:38

Less time than buying a new elliptical! ☺

About an hour and a half working on the part. I’m not counting the time spent wandering around the toy store (Northern Tools) or assembling the grinders; I wouldn’t have done this if I didn’t expect to amortize that cost over lots of projects.

Michael K Johnson July 11, 2015 09:08

Spent almost an hour more working on it this morning. Used the angle grinder, too. Most of the hour was from getting ahead of myself while assembling it and having to take it back apart to do a missing step. Would have been much faster if I had gone a little slower. But it works again.

Imported from Google+ — content and formatting may not be reliable