MIG Home Repair

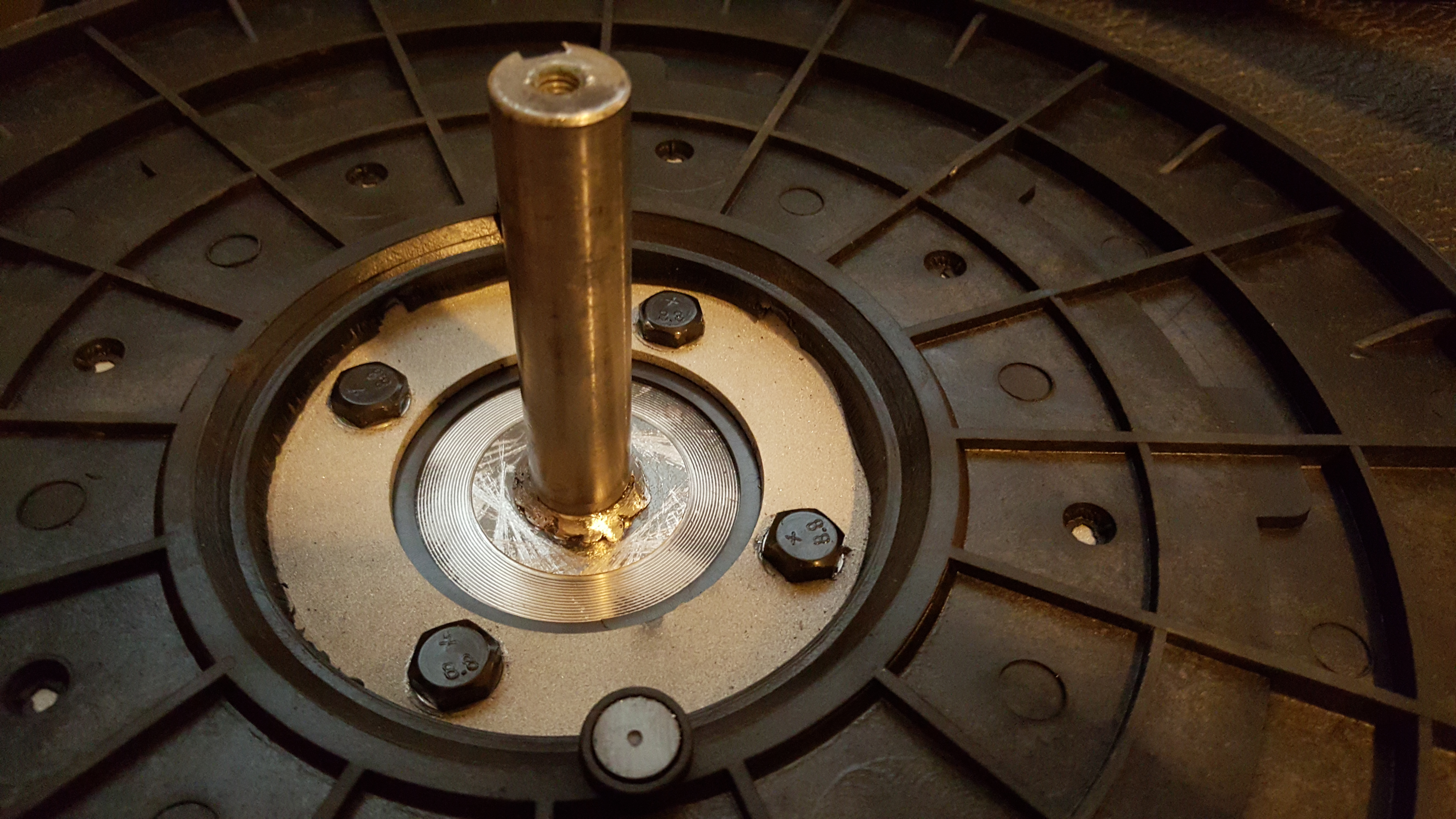

A MIG welder was not the right tool for the job, and I’ve never tried welds quite like this before. It’s not perfectly straight; the attached pulley wobbles about 2mm or so at the outside. I thought I had to grind down the bead on the outside to fit, and it turns out I needn’t have done so and may have weakened it a bit doing so. But it’s probably stronger than when we bought it, and it works, even though the weld is ugly.

Unexpected success.

Now we have time to research quality elliptical machines. Given my experience with Johnson Health when I called for support for my treadmill I’m inclined to look into their brands. (When my treadmill squeaked, after just a few minutes of troubleshooting they sent me a new motor and let me install it myself instead of insisting on a “qualified” technician. Fixed the problem, too. Well done.)

Michael K Johnson July 09, 2015 21:31

Lasted exactly two months; it broke again this morning. The MIG welder was certainly not the right tool for the job. I did file the bead down too much.

If I only had a metal shop with a lathe…

Michael K Johnson July 11, 2015 09:00

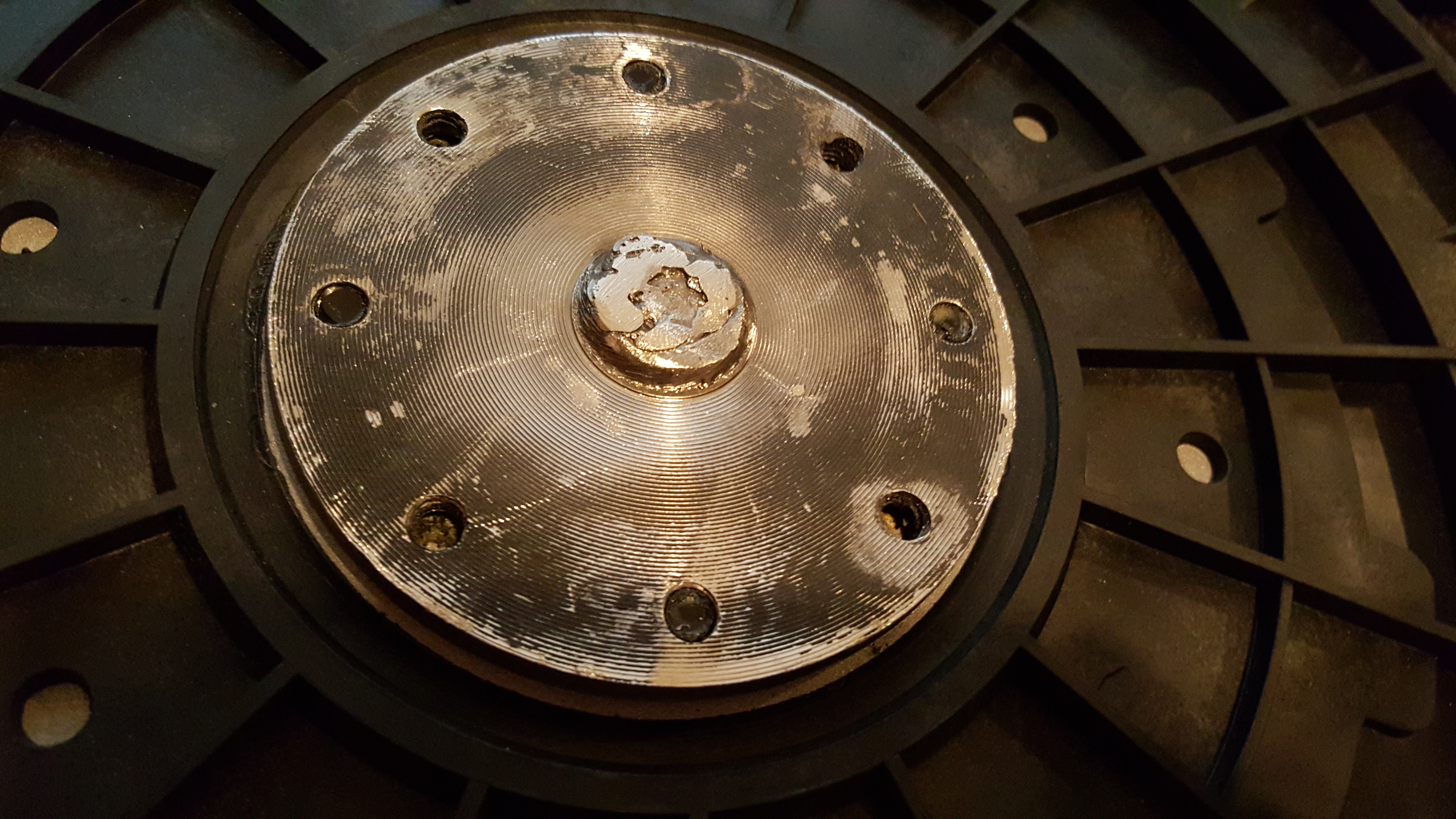

Ugh. I used this picture as a reference for aligning the bolts with the key slot, forgetting that this was the picture with the alignment wrong. The key slot needs to be aligned pointing directly towards one of the bolts for the crank arms to fit right. Making this comment in hopes that I notice it next time it breaks and I have to fix it again. :-)

Imported from Google+ — content and formatting may not be reliable