Experience with cast plate?

I’m tired of trying to tram a warped bed.

After realizing just how terribly warped the bed is in my Tronxy X5S, I’m looking at cast aluminum to replace it. Does anyone here have experience with something like 13”x13” (330mm x 330mm) cast aluminum to give evidence-based advice on thickness? Is 1/4” (6.35mm) thick enough for that size? It seems it would be good for lower thermal mass and quicker heating/cooling. Otherwise, thicker perhaps 3/8” (9.525mm) for more stability? My plan would be to order 13.25” x 13.25” and mount it with one screw in the back and two in the front for proper three-point tramming instead of the weird six-point system that the printer came with.

Weight is not a factor; I’m not worried about the lead screws being able to move it, and I’m going to use single-start screws as soon as I cut them to size so there will be way more torque than I could possibly need.

Griffin Paquette March 18, 2018 16:28

I do indeed. Had many pieces of MIC6 cut and printed with. If you have the bed where there is even force across it, you shouldn’t have any issues with 1/4in. I have a 3/8in plate for a delta and it takes over half an hour to cool down. I would just go with the 1/4 in.

Michael K Johnson March 18, 2018 16:33

+Griffin Paquette Thank you!

I suppose I could mount a spare fan blowing at the bottom to cool it down more quickly between prints, too. Then I wouldn’t feel like I need to switch between sheets of glass, maybe…

Kevin Danger Powers March 18, 2018 16:37

Have you considered using a piece of glass? It’s cheap and easy to use.

Michael K Johnson March 18, 2018 16:47

+Kevin Danger Powers I have glass. Four pieces of it. A it’s not perfectly flat itself and B it bends over the warped bed. With glass clamped to the bed, it’s still over 0.5mm off flat, which really sucks when you are trying to print .3 or .35 mm initial layers!

Until I realized how badly warped the bed was, I was going to buy mirror to replace the window glass because it is supposed to be flatter and 3mm mirror should be stronger than 2.5mm window glass. But now I realize that would be a waste of time and money. I do that enough already without adding to the problem.

If I get MIC6/ATP5 I can always put mirror or glass over it for easy removal when I want, but I should no longer be compensating for warp in doing so.

Michael K Johnson March 18, 2018 17:08

looks like a good option. Shipping goes up by only about $1 if I also buy a 8.75” x 10.75” plate for my 220mm x 270 mm hictop i3 clone, which is also not perfectly flat. Hmm.

Cast Aluminum Tool & Jig Plate (ATP 5)

Michael K Johnson March 18, 2018 18:52

ATP-5 vs. MIC-6:

-

Brinell: 70 vs. 65

-

Yield: 18 vs. 15 ksi

-

Tensile: 41 vs. 24

-

Thermal conductivity: 81 vs. 82 btu/ft² hr⁰F

So ATP-5 should be stiffer (tensile strength), harder (against wear), and thermal conductivity close enough that I couldn’t possibly notice the difference. ATP-5 it is.

Now I just need to decide how to heat it.

Michael K Johnson March 18, 2018 21:19

I guess the available options are to buy a 300mm x 300mm silicone heating pad, where it’s probably more efficient to use an SSR and 120V than to keep using my 24V power supply, or to cut back the slightly bulging middle of my existing bed and thermally bond it to the cast plate. (Thermal paste?)

Any other options?

Griffin Paquette March 18, 2018 22:31

+Michael K Johnson no problem! By far my favorite material to print on.

N. Y. March 18, 2018 23:12

For your “glass”problem.. dont use just glass, glass isnt glass.

U can buy glass thats very plane, also there is glass that u can heat without deforming himself and also dont use glass thats thinner than 4mm because it would bend in some cases… If ur heatbed isnt plane(mine isnt) and u use to strong clamps ur glass will bend, i had this problem, Weak clamps are better and it dont need much strength to hold ur glass in position.

The best for glass in my eyes is a soft thermalpad (watch for max temp also not to thick max 1mm) between heatbed and atleast 3mm better 4mm thick Borolsitglass (u should see maximum thickness difference in the description, if not ask for it)

Then buy clamps that only apply some pressure if u clamp ur skin and it hurts its way too strong.

Then ur bed gives the heat and the glass gives the plane surface. mark the position of ur clamps on the glassplate also use always the same clamps on the same spot, u wont find clamps that have all the same pressure unless u buy thousands and search for them😁 I use 4clamps not more not less close to the edges, two on the same side in one line with the two on the other side. If u do this u will minimise zeroing and deformed heatbed problems.

I dont even use the thermal pad, i wanted first but then i tryed and only bend my clamps so the dont have much pressure anymore. 0.05mm difference now, at all 4edges, from edge to edge and from edge to the middle.

With the pad im pretty sure it would be less but its fine for me.

Negativ point u need a minute more to heat i up with the pad i think.

Hope that could help u a bit. But rly dont underestimate to strong clamps. Its a curse😂

N. Y. March 18, 2018 23:15

+Michael K Johnson no thermal paste, its dirty shit. Thermal pads or something like that, nearly same effect and way cleaner to work with.

N. Y. March 18, 2018 23:44

For faster cooling/restart for printing i would use on top of ur “perfect plane” surface a very thin glass1-2mm , i would go for 2mm because stability, but it would need a bit longer to heat up.

Clamp it soft to ur buildplate.

Buy two glassplate of the same thickness, mesure the thickness after buying/zero both plates an look for the difference, mark them(position and everything so u always put them in like u did before). Then u can switch ur buildplate very fast with no problem, only need to set ur offset for the right plate if there is a difference, and wait 2min so ur thin glass is on temp.

If u have a moving bed in x/y i would not recomend it if u use a thick glassplate like me as a plane surface to print on and add another thin one. To much weight in my eyes. Then ur heatbed have to be plane enough that u could directly use a thin glassplate.

And like said in the other comment, use good glas like borolsit or something like that.

Stephanie A March 19, 2018 01:30

I got the atp5 from Midwest steel supply, it’s good stuff. One note, they don’t package it very well, maybe you can request they wrap it in thick cardboard.

I will never use glass again. It’s flatter and heats more evenly.

N. Y. March 19, 2018 01:41

+Stephanie S yeah thats why i let my heatbed heat up and wait 5min after it reached my wanted temp. I love glass, but i can totaly understand using that stuff when u wanna save some minutes.

Michael K Johnson March 19, 2018 06:15

+Stephanie S Decades ago, I drove past their location more times than I can count. Now I can’t take the “pick up” option any more. So I’ll take the hint!

Daniel F March 19, 2018 15:51

6mm (around 0.25”) cast aluminium works well as a build plate on my printer, size is 310x310mm. 360W, 230V silicon heater with SSR. On top I use a 3mm thick 30x30cm mirror tile. Printer is gantey style so bed is not moving.

Michael K Johnson March 19, 2018 17:00

+Daniel F why mirror on top of the aluminium? Quick switch? Glossy surface? I’ve been thinking of surfacing the aluminium with kaptan for gloss and higher thermal conductivity than a glass sheet. I guess I could add a glass or mirror plate when I want gloss, and just add Z offset for it when slicing. So I don’t really have to choose…

Daniel F March 19, 2018 19:52

You can remove it to coat with whatever you need for the filament you are printing to stick. Kapton, glue stick, etc. I use 3d lac, it’s rebranded hairspray, abs and asa-x sticks well to it and the part pops off when it cooles down. The mirror tile is cheap, easily available and flat. It adds some time to heat up as glass doesn’t have good thermal conductivity. You can also remove the glass to clean it.

Michael K Johnson March 19, 2018 19:58

Yeah, I use glass now, primarily with hair spray, also kaptan and pva glue. Was curious which reasons mattered to you, that’s all.

The more I think about it, the more I like the idea of printing on PEI or kaptan on the aluminum with an option to add mirror for other surfaces, depending on which plastic I’m using.

Michael K Johnson March 19, 2018 20:08

Really interesting design at

Preston Bannister March 20, 2018 13:27

FWIW, about heated beds.

Note the comment from Kyle offering to make a properly machined and assembled bed.

Getting close enough in my printer build to need to sort the print bed. Fran…

Michael K Johnson March 20, 2018 18:29

Thanks! Your point in there about steel and glass having lower thermal conductivity than aluminum and therefore having more even heat distribution makes sense to me… More fuel for my bimodal printing idea.

Preston Bannister March 20, 2018 19:29

+Michael K Johnson Though you can make steel quite thin, but glass not so much - especially for a removable bed surface.

In truth, wondering if the cost trade-offs are seriously bimodal. The ideal solution would be a thick aluminum plate with a milled-flat top, then a removable thin spring-steel build plate (held by magnets). That would be the ideal solution. Dead-flat top surface, with fast heat-up.

Problem is that 400mm milled plates (for the other printer I am building) seem to be about $300 (or more). That is a lot.

Aiming at smaller cost, bought a 400mm square of sheet aluminum for ~$50 (delivered). The plate is flat (near as I can tell) in one dimension, a bow of <1mm in the other. Pressing the sheet against a flat surface, fairly small force is needed to bring the plate to flat. Attaching the plate to a bit of extrusion might be enough. Maybe.

Maybe the lowest-cost way to get a flat bed is to use glass, with an aluminum sheet glued to the bottom. Not ideal in term of heat times, but cheap and flat. Could still use a spring steel removable build plate.

Or is there some other approach?

Michael K Johnson March 20, 2018 20:10

Whether you can make it flat when it’s cold is a different question from whether it’s still flat when heated.

For me, I have no question whether I’m going to buy milled cast plate. Either ATP-5 (probably from Midwest Steel Supply) or MIC-6 (which I can buy on my way home from work) depending on total cost; they are both good enough and definitely better than rolled plate. I’m almost certainly going to use AC heat pad, an SSR, and a TCO to protect against the common SSR failure mode.

While I really like the idea of the kinematic mount, I’ll save that for another day—after I have, or have access to, at least a CNC router if not a mill. There’s enough slop in the mounting holes on the X5S bed supports that I can bury M3 in the plate with loctite, not showing any exposed screw head on the printing side of the plate, and expansion won’t hurt.

Michael K Johnson March 20, 2018 21:07

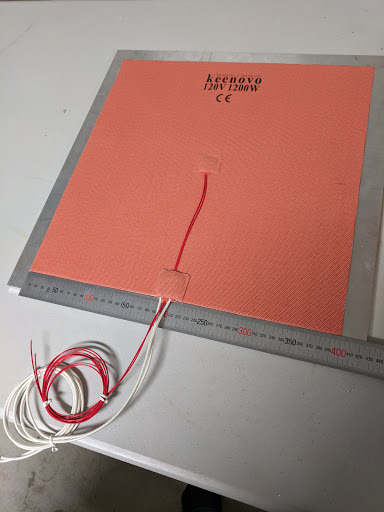

300mm x 300mm Keenovo heater: — same price from Amazon as the Keenovo aliexpress store. Yeah, I’ll have to wait a little while for the edges to heat up if I’m printing something big.

Preston Bannister March 20, 2018 21:18

Bought mine through Aliexpress. (This is not for the X5S.)

Michael K Johnson March 20, 2018 21:49

I’m confused by you saying it would be $300 or more for milled plates, by the way. I see 400x400, 450x450, and 500x500 variously in your comments, but none of those sizes closely approach $300 AFAICT. 450x450mm 1/4”is $65 for ATP-5 from Midwest Steel. 3/8” 20”x20” is still under $100, and probably about another $25 or so to ship.

Preston Bannister March 20, 2018 22:18

+Michael K Johnson Will admit some confusion, on this topic, in terms of process, alloy, and cost. Went through the choices months ago, and made my best guess. In the above picture I have a 450mm square aluminum bed with a 400mm heater. (The print surface is meant to be 400mm.)

Pricing the cast ATP-5 plate from MidWest, the same size square should be a bit over $100 shipped. The zinger is “flat within .015 inch” or 0.38mm … which is a bit large compared to layer height. Could get lucky. Or could need to flatten the plate, somehow. If I need to flatten the cast plate, is that still an advantage over less expensive sheet?

Punted. Ordered the sheet, to see if that could be sorted.

The “right” way to do this would be to get a proper milled top surface, but that seems to get us into the ~$300 price range.

Michael K Johnson March 21, 2018 06:16

I had the same worry, until I learned that the “flat within .015 inch” is a max spec across the full width of the uncut piece and not typical; also any variation across the full width is not representative of the variation on a cut, which I’ve typically seen described as “mirror-flat”. It’s already a “proper milled top surface”, apparently done with a huge facemill. See and http://www.howardprecision.com/aluminum/aluminum-cast-tool-jig-plate-stock-list/alca-5 (Alca 5 and ATP-5 are the same for our purposes; same alloy and similar manufacturing processes, as I understand it.)

Milling rolled sheet wouldn’t help you much because the internal grain orientation and stresses lead to uneven expansion when it is heated. Cast plate doesn’t have those internal stresses. Different alloys give you different properties; MIC-6 is 7000-series (purer aluminum IIRC) and is softer and more difficult to mill; ATP-5 and Alca 5 are both 5083 aluminum-magnesium alloy and are harder and mill more easily; they have less thermal expansion and I think around 1% lower thermal conductivity. All three have consistently good results reported for 3d printing.

Material question: What is MIC 6

Preston Bannister March 21, 2018 13:42

On a related note, did a bit of work with the TronXY X5S print bed. Added 1/8” cork to insulate the bottom. put three lengths of aluminum extrusion underneath, between the screws.

Before the print bed sagged between the rails. Adjusted to ensure the bed is parallel to the gantry. Now the aluminum bed is dead-flat, near as I can tell.

Clipped on the plastic (plexiglass?) print bed. Started dialing in the nozzle height … and found there is now a slight crown(!) to the print surface. (From the clips pressing on the thin plastic?)

Right.

Maybe I should just print on the aluminum. :/

Michael K Johnson March 21, 2018 20:13

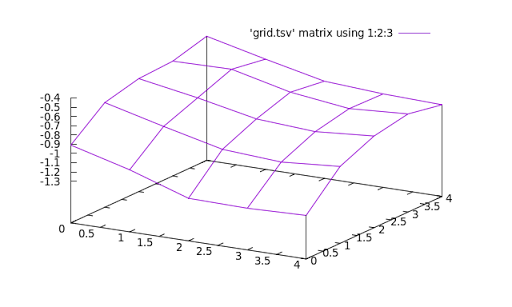

A picture is worth a thousand words sometimes. I have referenced the bed supports to the frame and the bed to the supports, but haven’t yet tried to level the bed to the nozzle on average and I intentionally set Z a bit high for now. I wanted to get a sense what things look like now. This is with glass clipped with the supplied bulldog clips to the bed, with bed and nozzle preheated for about 10 minutes prior to measuring.

I entered 25 data points from a bed leveling session into a TSV file:

-0.91 -1.08 -1.29 -1.3 -1.28

-0.62 -0.78 -0.93 -0.97 -0.92

-0.53 -0.64 -0.77 -0.81 -0.76

-0.51 -0.5 -0.65 -0.73 -0.69

-0.41 -0.56 -0.7 -0.74 -0.76

gnuplot> splot ‘grid.tsv’ matrix using 1:2:3 with lines

It looks vaguely hyperbolic. There’s only so much I can do with this.

Michael K Johnson March 21, 2018 20:52

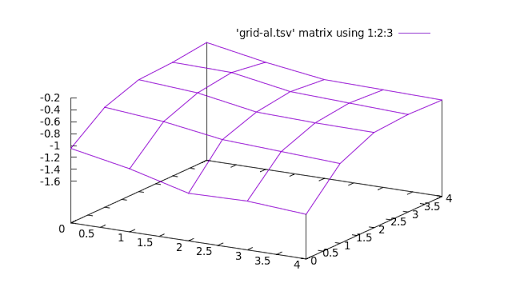

Measuring bare aluminum, the overall pattern looks similar.

Michael K Johnson March 21, 2018 22:01

gnuplot is autoscaling the axes because I didn’t provide a scale. This is useful for seeing the overall shape of the data. Here’s what it looks like after many rounds of leveling using the bed level Marlin feature to help calculate how much to turn the leveling screws (0.5mm pitch M3 screws) to adjust; trying to have minimal tension on the springs; still .4mm variance between lowest and highest points is the best I seem to be able to do with the shipped bed at 60⁰ and nozzle at 200⁰

Michael K Johnson March 21, 2018 22:18

One more round got me to .33mm total variance and .1mm in the middle of the board (middle ~150mm).

Makes me think that if I clipped mirror to the sides that do not have the “leveling” screws, I might reduce that variance further and get acceptable prints until I get a better bed. But that’s a project for another day.

Michael K Johnson March 21, 2018 22:41

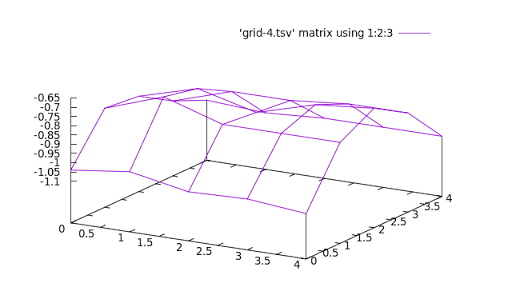

I don’t have mirror available right now, but clipping glass on at the sides gives me worse variance; .61mm total and .36mm in the middle (as previously defined). This surprises me since I’ve clipped it along the relatively flat axis so as not to bend it over the “saddle” that shows in the data for the aluminum. I’m wondering whether the glass actually has a stronger tendency to warp than aluminum, because of a lower thermal conductivity relative to its coefficient of expansion, thus a larger temperature gradient from bottom to top of the glass plate. I’m curious enough to buy mirror to test, but this seems to confirm the idea of using PEI on cast aluminum.

It’s easy to find 300mm x 300mm (or 12” x 12”) PEI sheet, but 330mm x 330mm (or 13” x 13”) seems to be scarce.

[EDIT]

Actually, all the variance is front-to-back; it’s pretty flat, just not level. So probably +M. Wie’s point about exact position of the clips mattering is exactly what I’m seeing here, and playing with it I could probably improve this a lot. I’ll have to explore that when I next have a chance.

Michael K Johnson March 22, 2018 21:40

Clipping only at the back reduced overall variance with the glass, but it’s still showing more variance than the plain aluminum.

The metal store I visited this morning had no MIC-6 and hadn’t heard of ATP-5, and wondered whether 5083 was steel. ☺

Preston Bannister March 23, 2018 00:29

One approach…

For a (conservative) 12” (304mm) square bed (small for rails):

$ 21 - BuildTak Printing Surface.

$ 35 - BuildTak FlexPlate.

$ 53 - 025” ATP-5 Aluminum plate from MidWest Steel (shipped).

Subtotal ~$109.

Plus…

$ ?? - (magnets to bore/bond into the plate & hold the bed)

For a (daring) 16”(406mm) square bed.

$ 21 - BuildTak Printing Surface.

$ 50 - BuildTak FlexPlate.

$ 74 - 025” ATP-5 Aluminum plate from MidWest Steel (shipped).

Subtotal ~$145.

https://www.buildtak.com/shop/https://www.buildtak.com/shop/

Cast Aluminum Tool & Jig Plate (ATP 5)

Preston Bannister March 23, 2018 00:45

BTW, if you buy borosilicate glass, then it will not change dimension when heated. More expensive than ordinary glass, and still a poor thermal conductor, but better than plain glass.

Michael K Johnson April 19, 2018 19:04

+Stephanie S I also bought ATP-5 from Midwest. I took your advice and asked them to wrap it in extra cardboard, but that was clearly ignored. I bought two plates, one for the X5S and one for my i3 clone. Both plates have some scratches in the plastic covering that look like the surface may be scratched. Planning to mill it (maybe this weekend) for a kinematic mount before putting the Keenovo pad on it.

I have a different order from Howard Precision’s “random rack” including some Alca-5 (which seems to be functionally identical to ATP-5) and I’ll see how that’s packaged when it arrives.

Michael K Johnson May 18, 2018 18:56

Promised update, a little late: Howard Precision’s pieces were a bit better packaged, with less swarf included, and with with layers of cardboard between pieces. Also, the pieces had a much cleaner edge and were cut more square than the pieces from Midwest.

They don’t have as easy an online order experience. You end up actually talking to a person after putting together a quote online. The quote was inclusive of shipping. They don’t take credit cards online; they take them by fax or phone; they are clearly oriented towards taking POs from businesses. But they did a good job. While I am generally satisfied with Midwest, I think I’ll check with Howard Precision first.

Michael K Johnson July 07, 2018 22:47

Forgot to follow up — once I got the plastic off, I saw that the plate from Midwest was also dinged multiple places on both sides. Not awesome. Howard Precision definitely did a better job.

Imported from Google+ — content and formatting may not be reliable